From Kitchen to Laboratory: Analysis of Multiple Application Scenarios of Latex Gloves

Latex gloves have already surpassed the traditional medical field and become an indispensable helper in people's daily life and work environment. Whether it is a housewife who is busy cleaning greasy tableware in the kitchen, or a researcher who needs precise operation of experimental equipment, latex gloves have won wide acclaim for their excellent flexibility and protection.

In domestic cleaning, they can isolate the irritation caused by detergent on the hand skin; and in professional situations, they provide the first barrier against chemical attack. This adaptable feature makes latex gloves suitable for almost all manual work scenarios.

Both texture and performance: the key characteristics and manufacturing process of high-quality latex gloves

high quality latex gloves are not just simple rubber products, but precision-machined functional tools. The natural latex material itself has extremely high elasticity and extensibility, which ensures that the wearer will not feel discomfort even if it is worn for a long time. At the same time, the modern production process also gives it a stronger durability and tear resistance.

Every link is strictly controlled to ensure the excellent quality of the final product-focusing on purity screening from the beginning of raw material collection, using advanced technology to remove allergens in the molding process, and verifying whether the indicators are up to standard through multiple tests.

Protection: How Latex Gloves Resist Chemicals and Bacteria

When talking about the word "protection", many people may first think of preventing physical damage, but in fact, the real strength of latex gloves lies in chemical and biological defense functions. Its dense molecular structure can effectively prevent most liquids from penetrating into the internal space, thus forming an indestructible line of defense to prevent external threats from contacting the user's skin surface.

Not only that, many high-end models also add an antibacterial coating treatment process to further enhance the ability to resist microbial aggression, making every touch more secure and reliable.

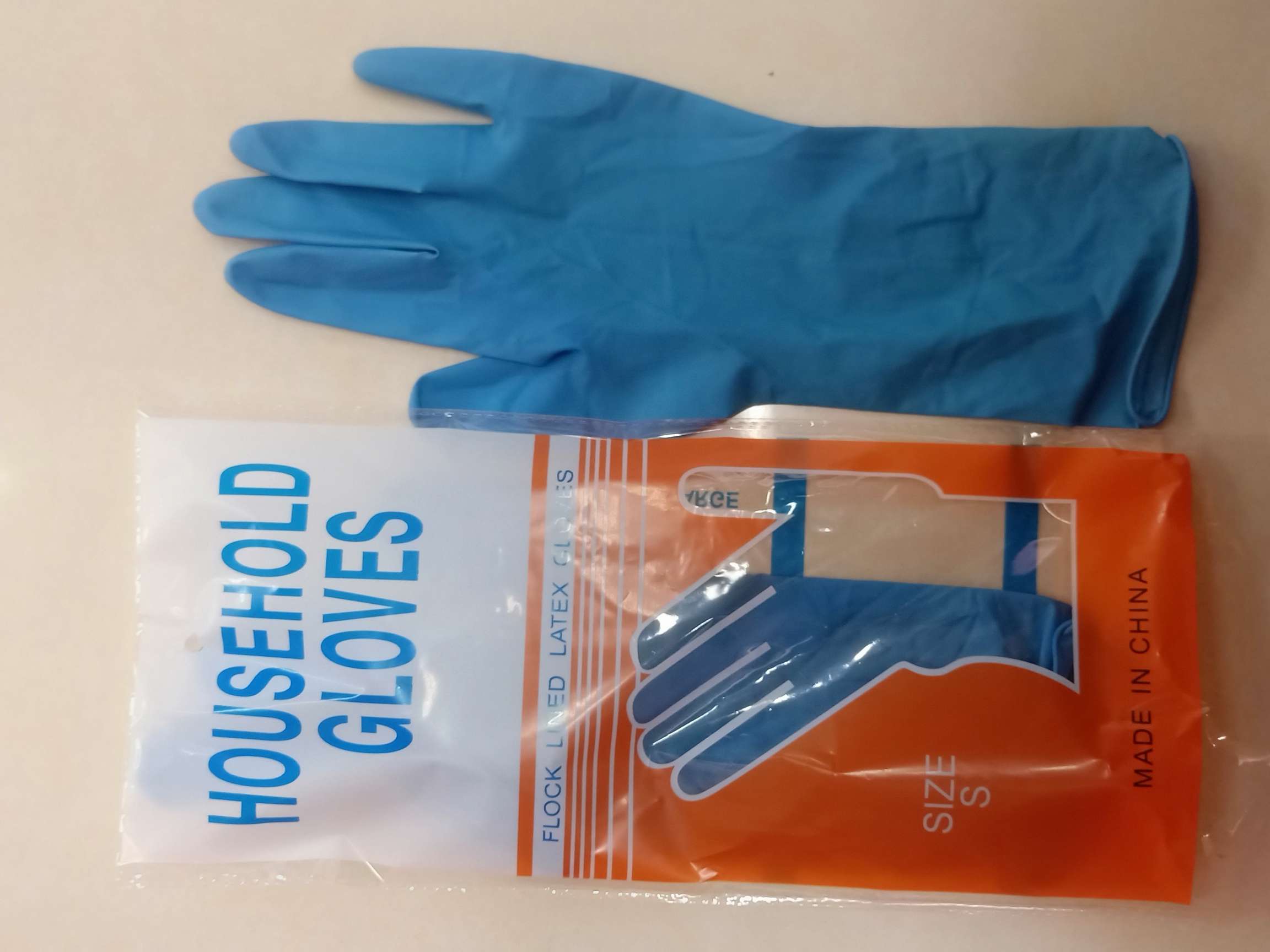

Glove purchase tips: match the right glove type and size according to the demand

In the face of the wide variety of options on the market, it is particularly important to correctly select the ideal model for your specific purpose. The primary consideration is, of course, the special requirements of specific application scenarios, such as the food industry's preference for powder-free design to avoid contamination of finished food products, while professional medical-grade products with higher intensity and lower risk of allergic reactions are preferred for health care workers working in high-risk environments.

The second is the size problem can not be ignored. Too tight will affect blood circulation and cause increased fatigue, and too loose may lead to inflexible control, reduce work efficiency and even cause safety accidents. Therefore, it is very important to accurately measure the circumference of the palm and select the most suitable specification according to the reference table provided by the government.

Daily maintenance tips: an effective way to extend the life of latex gloves

Although the concept of one-time use is deeply rooted in the hearts of the people, if the gloves that have been touched by some non-critical parts can be reused within an appropriate range, it can not only save resource costs but also reflect the awareness of green environmental protection. In order to achieve this goal, the following points should be paid attention to:

rinse the internal and external residues immediately after each detachment and dry and store them to avoid direct sunlight leading to accelerated aging; In addition, regular inspection for small cracks and timely replacement of damaged individuals is also one of the important measures to maintain stable operation of overall efficiency.